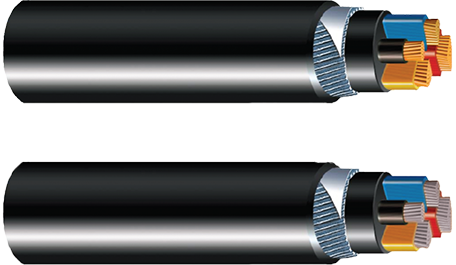

Type : 2XFGY / A2XFGY

Voltage : 600 / 1000 V (permissible Service Voltage : 720 / 1200 V)

Special Type

- 2XFGY(FP*)/2XFGY(FG*)

- 2XFGY-FR/A2XFGY-FR

- 2XFGY-FRLS/A2XFGY-FRLS

- 2XFGY-LSZH/A2XFGY-LSZH

- 2XFGY/A2XFGY-HRFR-150°

Specifications / Rating

ASTM: B-3

BDS IEC: 60228&60502-1

VDE: 0271

IEC: 60331&584

IS: 7098-1 & BS: 5467

Applications

- Indoor

- Outdoor

- Underground

- In water

- Power plant

- Switch gear

- Generator

- Industrial

Construction : Annealed Copper or Aluminium Conductor / XLPE Insulation / PVC inner sheath / Galv, Steel strip armoured / PVC outer sheath.

| Cross Sectional Area | No. & Approx. Diameter of wire Cu/Al | Nominal Thickness of Insulation | Diameter of steel strip armour | Nominal Thickness of Sheath | Overall diameter (approx) | Approx Weight of Cable | Max. DC resist. of conductor at 20°C | Current rating at 30°C in ground | Current rating at 35°C in air | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Al | Cu | Al | Cu | Al | Cu | Al | ||||||

| Core x mm2 | No./mm | mm | mm | mm | mm | Kg/Km | Kg/Km | ohm/km | ohm/km | amps | amps | amps | amps |

| 3×25 rm+16 rm | 7/19 wire 7 wire |

0.9 0.7 |

4×0.8 | 1.8 | 25.8 | 1744 | 1299 | 0.717/1.15 | 1.2/1.91 | 130 | 94 | 120 | 96 |

| 3×35 sm+16 rm | 19 wire 7 wire |

0.9 0.7 |

4×0.8 | 1.8 | 27.7 | 2028 | 1236 | 0.524/1.15 | 0.868/1.91 | 155 | 114 | 150 | 117 |

| 3×50 sm+25 rm | 19 wire 7/19 wire |

1.0 0.9 |

4×0.8 | 1.9 | 31.2 | 2915 | 1507 | 0.387/0.727 | 0.641/1.20 | 190 | 133 | 190 | 142 |

| 3×70 sm+35 rm | 19 wire 19 wire |

1.1 0.9 |

4×0.8 | 2.0 | 35.5 | 3793 | 1823 | 0.286/0.524 | 0.443/0.868 | 225 | 164 | 230 | 179 |

| 3×95 sm+50 rm | 19 wire 19 wire |

1.1 1.0 |

4×0.8 | 2.2 | 40.0 | 4881 | 2262 | 0.193/0.387 | 0.320/0.641 | 260 | 196 | 270 | 221 |

| 3×120 rm+70 rm | 37wire 19 wire |

1.2 1.1 |

4×0.8 | 2.3 | 43.4 | 6252 | 2698 | 0.153/0.286 | 0.253/0.443 | 295 | 223 | 305 | 257 |

| 3×150 sm+70 rm | 37wire 19 wire |

1.4 1.1 |

4×0.8 | 2.4 | 47.3 | 7023 | 3205 | 0.124/0.286 | 0.206/0.443 | 330 | 249 | 350 | 292 |

| 3×185 sm+95 rm | 37wire 19 wire |

1.6 1.1 |

4×0.8 | 2.6 | 52.7 | 8975 | 3808 | 0.0991/0.193 | 0.164/0.320 | 385 | 282 | 410 | 337 |

| 3×240 sm+120 rm | 37/61 wire 19 wire |

1.7 1.2 |

4×0.8 | 2.8 | 58.5 | 10669 | 4500 | 0.0754/0.153 | 0.125/0.253 | 425 | 327 | 470 | 400 |

| 3×300 sm+150 rm | 61 wire 37 wire |

1.8 1.4 |

4×0.8 | 2.9 | 66.6 | 13863 | 5435 | 0.0601/0.124 | 0.100/0.206 | 478 | 368 | 584 | 455 |

| 3×300 sm+150 rm | 61 wire 37 wire |

2.0 1.6 |

4×0.8 | 3.4 | 78.1 | 18015 | 9266 | 0.047/0.0991 | 0.0778/0.164 | 590 | 459 | 700 | 544 |

| Note: As per customer requirement we shall provide Fire proof/resistant cables (25 mm2 to 300 mm2) which can resist fire temperature of 750C with circuit integrity. Also we shall provide Fiber glass wrapping XLPE insulated cables (35 mm2 to 400 mm2) whose max. operating conductor temperature is 180°C without short circuit & Insulation life is almost double. | |||||||||||||